The Forté Series 8000 measures the average moisture content and Air-Dry % of every bale of pulp that you manufacture. The measurement is made automatically, in real time; right in the bale press while each bale is being produced.

Main Application shows real time bale

placement, weight and % AD

(click image to enlarge)

Why Measure Moisture?

Accurate moisture determination has a direct effect not only on quality, but also on pulp mill invoicing and bottom line profits.

Pulp that is too wet will cause customer complaints. Pulp that is too dry wastes energy and can cost your company profits due to under-billing. Some mills under-invoice to ensure customer satisfaction: a customer will never complain if he is getting more than what he paid for. Other mills may under-invoice because they do not have a reliable, accurate method to measure moisture content.

Why Use a Forté System?

Other moisture analyzing methods take hours to complete, destroy the sample, require highly trained personnel, are not as accurate, and/or cost a lot more than a Forté Moisture Measurement System.

With a Forté System, you can achieve 100% sampling and know that you are billing for all the fiber that you ship. At the same time, your customers’ will benefit by knowing they are getting exactly what they are paying for.

The most common moisture measurement method is Laboratory Oven Drying. If done correctly, this method is very accurate but it measures less than 0.001% of your production. How can a mill possibly invoice accurately when such a small amount of pulp is tested?

Laboratory Oven Drying is a multiple step, labor intensive process, so it allows for the possibility of human error. Since these tests often take hours to complete, they are useless for controlling energy consumption.

A scanner works well for measuring moisture content for the purpose of controlling the dryer. However, if you are looking to determine invoice weight, a Forté System is much better. A scanner measures in a zigzag pattern as the pulp web moves into the cutter/layboy. Inherently, much of the pulp is missed. By using a Forté Moisture Measurement System, you can confidently state the Air-Dry % of each and every bale, because each and every bale has been measured.

How Does the Forté System Work?

The secret of each Forté System is in its electrode sensor and signal generator. The Forté electrode, which is mounted to your bale press platen, passes a harmless, low frequency electromagnetic field through your entire bale.

The Forté computer receives the electronic moisture reading and the digital weight input from your existing scale display. These numbers, together with the appropriate calibration constants for the product being measured, are used to calculate the % Air-Dry.

The Forté System is calibrated using laboratory oven tests. Our experienced engineers will assist with this at the time of installation. Once a careful calibration is completed, the Forté can operate effectively for many years.

Forté Provides All of the Information You Need

The data that Forté collects is stored on the Forté computer and can be output to a mill-wide information system. The user interface is configurable as are the periodic reports which can be generated automatically.

Forté Systems provide information by bale, unit, lot, shift and/or day. User defined fields can be used to enter other Quality parameters which will become part of each bale’s record. A record of each measurement and its associated data is stored in the archives and can also be sent to the mill’s network. Production data for the last 24 months can be viewed and/or printed from the Forté computer. The software application calculates and prints the total tonnage and average moisture, resulting in comprehensive management information.

In addition, the Forté software application can output data to your Bale Marker, display easy to read graphs of % Air-Dry and weight, and provide an output to DCS (distributed control systems), remote displays, and other peripherals. An optional application can help control your cutter/layboy by using basis weight and sheet counting to signal the cutter/layboy when to drop.

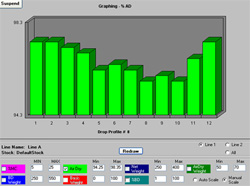

Profile Bar Graph which shows the % AD

and/or weight across each drop

(click image to enlarge)

Forté Systems are Flexible and Affordable

Forté designs and installs complete systems for any type of mill configuration: one cutter/layboy to multiple presses, two cutter/layboys to a single press, or any other combination to suit your needs.

Only Forté provides 100% sampling and the direct means to improve yield by one-quarter of one percent or more. A Forté System is the key to precise accounting for every kilogram of pulp produced in your mill. The typical Return on Investment is measured in months rather than years.

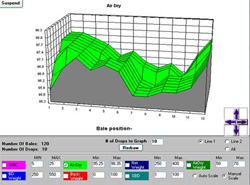

3 Dimensional graph of % AD or

weight by bale position and drop

(click image to enlarge)

Advantages of the Forté Series 8000 Pulp Moisture/Weight Measurement System

- Increase Tons Billed

- Improve Accuracy by 100% Sampling – Measure All of the Pulp in Every Bale

- Measure Moisture in Real Time, Not Hours Later

- Maximize Invoicing Weight without Risk of Customer Complaints

- Optimize Drying Function - Save Energy

- Reduce Testing and Production Labor

- Improve Quality

- Provides Accurate Production Records

- Monitor Pulp Moisture Distribution to Reduce Frequency of Web Breaks

- Stabilize Bale Size and Weight using Forté Drop Control

- Archive and Print Production Data Records