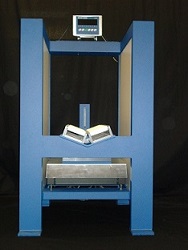

The Forté 7000 and 6000 Series are designed specifically for measuring the moisture and weight of textile yarns in the form of Cones, Bobbins, Skeins, Tops, Bumps, Loose Fiber, etc. The 7000 Series test cell is vertical as shown in the standard desktop model. The 6000 series test cell is horizontal.

Standard Desktop Model

Why Measure Moisture?

Accurate moisture determination has a direct effect not only on quality, but also on invoicing and bottom line profits.

The entire process is analyzed to determine the proper weight and moisture. An accurate weight and moisture content allows invoicing at maximum allowable levels and savings in laboratory testing, The result is higher uniform quality, reduction in customer complaints, and better control of production.

Why Use a Forté System?

Other moisture analyzing methods take hours to complete, destroy the sample, require highly trained personnel, are not as accurate, and/or cost a lot more than a Forté Moisture Measurement System.

Forté is not a surface measurement. It “sees” 100% of the product sample. The measurement is taken in one second or less without contact, heat, or damage to the product. With a Forté System, more samples can be tested which leads to better control of production and the fibers can be billed at the maximum rate. At the same time, your customers’ will benefit by knowing they are getting exactly what they are paying for.

One commonly used moisture method is the Laboratory Oven Drying Method. This method takes hours and has multiple steps where there are possibilities of human error. If done correctly, this method is very accurate but it measures less than 0.001% of your production. Since these tests take so long to complete, they are useless for controlling energy consumption and quality. Fortè measurements are taken in a second or less. The information is gathered immediately and can be used for manufacturing adjustments much more effectively.

Main Application

(click image to enlarge)

How Does the Forté System Work?

The secret of each Forté System is in its electrode sensors and signal generator. The electrodes are contained within the two sides of the Forté Test Cell. The signal generator passes a harmless, low frequency electromagnetic field through the entire mass of your product – not just the surface.

The operator clicks on the initialize button on the computer, places the product in between the two electrodes on the Forté sample fixture, clicks on the test button, and a weight and moisture reading is displayed within a second.

The product sample is still in perfect condition and can be sold. This exclusive patented measurement is self-zeroing and virtually instantaneous. The Forté computer receives the electronic moisture reading and the digital weight input. These numbers, together with the appropriate calibration constants for the product being measured, are used to calculate the % Moisture Content or Regain.

The Forté System is calibrated using laboratory oven tests. Our experienced engineers will assist with this at the time of installation. Once a careful calibration is completed, the Forté System can operate effectively for many years. In fact, some systems have been in continuous use for 30 years or more.

This is a time-tested and highly efficient method used by textile, fiber, and related manufacturers who have increased their yield, productivity, quality and profits.

Forté Provides All of the Information You Need

The Forté System can be used for inventory and quality control by providing comprehensive, up-to-the-minute moisture/weight measurement for management information systems. Summaries are readily available by package, lot, period, shift and day. These summaries include all of the vital information and can be viewed, printed and saved. All of the information is saved in the Forté computer for 2 years and can be easily searched and accessed.

Vital information includes weight, % moisture, time and date, package number and grade. The way this information is displayed can easily be configured by the user. Remote indicators and displays can be included with the Forté system, or existing plant computers can be used for remote viewing and storing of the weight and moisture measurements. Wet/Dry and Heavy/Light alarm messages allow management and production workers to identify rejects instantly and ensure production quality while increasing yield.

The Forté system can easily be connected to bar code scanners, bar code printers and label printers. Variable and fixed data can be printed by large character label printers for product identification, warehousing and shipping.

Forté Systems are Flexible and Affordable

Forté Custom designs complete systems specifically for your product. We provide the direct means to improve both yield and quality. A Forté System is the key to quality control and increased billing on higher quality product.

The Series 7000 is configured based on the dimensions of your product(s) and your space constraints. The most common configuration is the desktop model, as seen in the picture above.

The 7000 Series can also accommodate larger individual products with floor models. A few examples can be seen to the right. Forté can provide just the moisture/weight measurement equipment or different size tables and/or consoles can be included. Forté will work with you to design the best solution for everyone.

Advantages of the Forté Series 7000 Pulp Moisture/Weight Measurement System

Kings Chair has rollers to ease

and protect products as it enters the cell

- Provides immediate and accurate moisture/weight measurements

- Allows testing of a large number of samples in less time

- Eliminates product waste and sampling errors in the laboratory

- Displays ISO verification data automatically

- Easy to operate by production workers

- Calculates and prints moisture content, commercial weight data, and time stamp